MIB-100™ Manual Inspection Booths

Model MIB-100™ (Current Version is:

3.1)

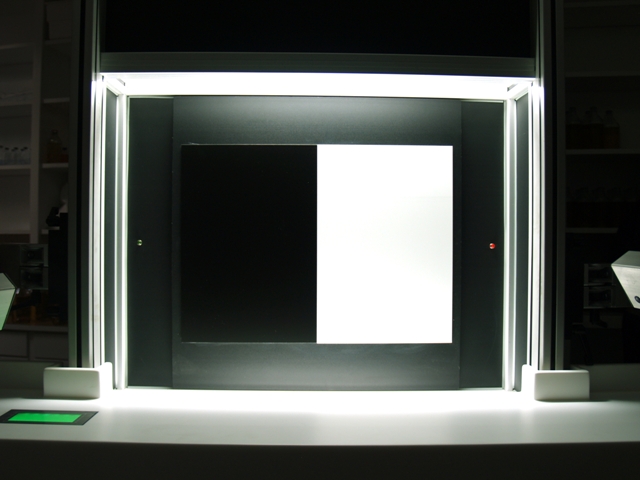

The Manual Inspection Booth (MIB-100™) in Production

Configuration is shown in Figure 1

below. The MIB-100™ is designed to provide a uniform illumination work

envelope and consistent inspection environment. The framework of the MIB-100 is

ergonomically designed and implements a recently patented balanced lighting

system that generates a 9.7 Liter inspection volume in which light

intensity is held within 10%, thus eliminating a major component for inspection

data variability. This large accurate inspection volume allows the inspector to

easily position the sample in the chamber. The MIB-100™

is the most popular of the floor standing MIB models and offers a wide selection

of add-on options to meet specific customer requirements.

Figure 1. MIB-100 (Shown with Standard curved

front Corian® armrest,

Optional Stainless Steel Side Shelves, Hydraulic Leg Lifts and Top Shroud Configuration)

The Production Configurations MIB-100 is designed to

handle higher inspection volumes and is customized to meet the material handling

used in your facility. The stainless steel side shelves are designed to

customer requirements to fit production product trays. They provide

adjustments for 2 axis of rotation and 3 linear translations to make the shelf's

position "just right" for each individual inspector. Best of all, the

adjustments do not require any tools! The locking screws have ratcheting

handles that allow the inspection crew to make their own adjustments for optimum

comfort. The side shelves are offered in two configurations, adjustable as

shown in Figure 1 or fixed as shown in Figure 2 below.

Figure 2. MIB-100D (Configuration with Stainless

Steel Armrest and fixed position side shelves)

The "D" option provides the ability to adjust light intensity from the operator

interface and the

"L" option provides the light curtains to initiate Pacer operations. This

model also includes the

larger LED Pacer lights and Audible Alarm.

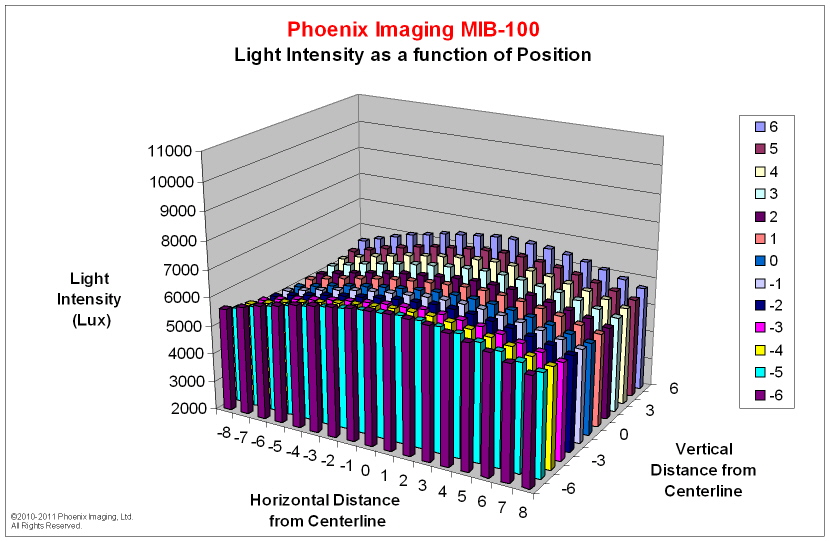

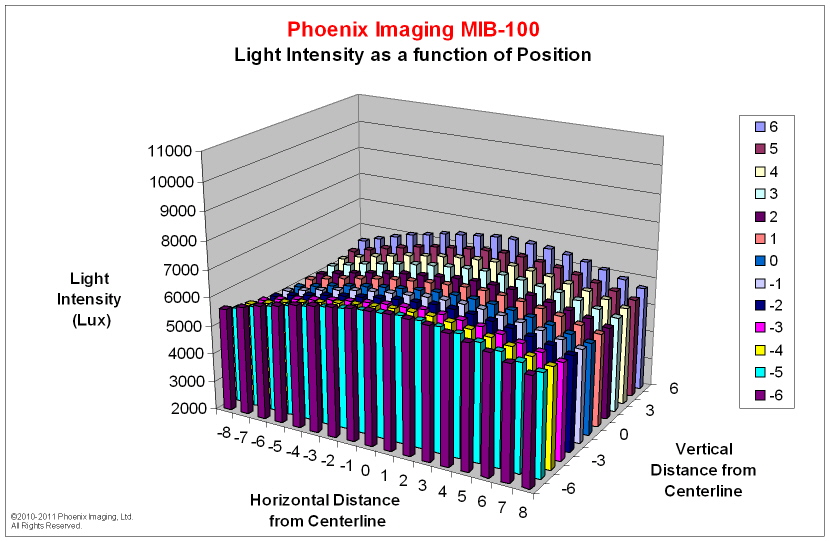

Figure 3. MIB-100 Lighting Uniformity in Inspection Volume

Lighting Profile of MIB-100 Manual Inspection Booth

Figure 4. Light Intensity Map of MIB-100

Consistent inspection results require consistent light

intensity within the inspection volume. The MIB-100 provides the most

uniform light intensity within an inspection volume available in a commercial

product. The lighting technique is so unique that it is patented!

Most lighting booths offer a single light source that is usually mounted above

the inspection volume. This top lighting technique produces a non-uniform

inspection volume that can have light intensity variations of more than 200%

over a very short distance (i.e. <50 mm). The probability of detection is

directly related to the amount of light in the inspection volume. Top

lighting technology makes it very difficult for inspection teams to achieve

consistent inspection results. The MIB series of manual inspection booths

have a relatively "flat" inspection volume with constant light intensity values.

The plot in Figure 4 above is representative of the lighting map found in the

MIB-100 product.

Inspection Sequence and Duration

All MIB-100 models include a programmable logic controller integrated into the

system to pace the operator inspection time. The PLC / operator interface

insures that samples are inspected for a designed amount of time and that the

result of the inspection disposition is correctly recorded. This is done using a

small flat panel display mounted just below eye level on the left side of the

booth (or flush mount on the Solid Surface armrest/shelf as

in the standard configuration) and within the sight of the inspector.

The backlight color on the operator

interface panel will indicate the mode of operation. The color is green when the

system is in a "Setup" mode; this mode allows the supervisor to review

results, set inspection parameters and the inspector to enter the

"Inspection" mode and to review results when the inspection shift

ends. The screen color is orange at the beginning of the

light background

particle inspection. During the actual inspection period the

screen will display a graphic count down timer and a red LED light will appear

just to the right of the inspection area. When the LED turns off the

inspection period is complete and the screen will then be illuminated with a red

background. The red background indicates that the dark background

inspection is about to begin. When the dark background inspection is

active a green LED just to the left of the dark background inspection area is

illuminated. When the Green LED turns off the dark background is complete

and the operator interface background turns green and requests the inspection

result to be entered. The inspector must then select, Re-inspect,

Good

or Bad to return to the

Light Background inspection screen.

The inspection system may also be setup for 18% Gray Card

Inspection. The gray background inspection screen will be illuminated with

an orange background. Once the "Start Gray Test" button is depressed the

screen turns red and both LED in the the inspection area are illuminated during

the inspection period. When the allotted inspection time has expired the

LED's turn off and the screen turns green. The inspector must then select, Re-inspect,

Good

or Bad to return to the Gray

Background Inspection screen.

The inspection results may viewed by depressing the

"Results" button on the Main screen. The system will reconcile up to

65,535 inspected containers.

US Patent No. 5,940176 granted and others patents pending.

To Download the current brochure in PDF format click on

the link below.

MIB-100 Brochure

|