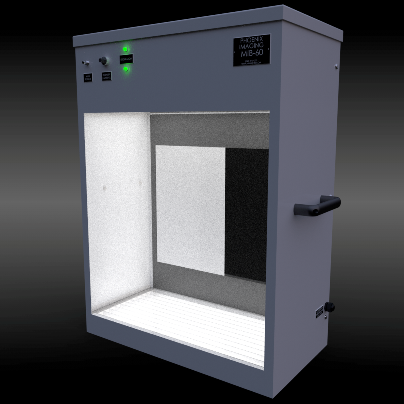

The Manual Inspection Booth (MIB-65™) in Standard Configuration is shown in Figure 1 below. The MIB-60™ and MIB-65™ are a new Manual Inspection Booth design that implements LED lighting panels with a new digital LED controller (model PS-2060-PFC). The LED controller has a large dynamic range and allows a 8:1 intensity control. The LED controller has power factor correction built in and is designed to operate on input voltages of 90 - 220 VAC. As will our other lighting controllers the system has active loop feedback that monitors the LED output with photo-diodes built into the panels. The system provides a uniform illumination work envelope and consistent inspection environment in a volume small enough to place on a table of laboratory counter top. The high frequency power supplies operate at >25 KHz and have active-loop feedback control to maintain precise luminous flux. The power supplies insure balanced lamp output over the entire range of control. There is a potentiometer mounted on the front of the enclosure that allows precision adjustment of the lighting level. In conjunction with the novel lamp separation adjustment the light intensity of the system can be adjusted between 2000 and 8000 Lux in the inspection volume.

Figure 1. - MIB-65

The metal enclosure is painted with white powder coat and is available in MIB-60™ and MIB-65™ styles. The MIB-60™ and MIB-65™ are also available in stainless steel configurations for clean room use. The enclosure dimensions are 30.5" W x 14" D x 36.25" H (with handles), weighting approximately 125 lbs.

The White /Black background is replaceable if it is damaged or is marred. The background is also reversible so the white and black sides can switched in the inspection process. The background can also be purchased as all white, all black or 18% Gray Card..

The MIB-60™ (not shown) provides a PLC and Operator Interface for lamp status and Pacer controls (includes RED and GREEN LED's on the side of the black / white inspection panel). The MIB-65™ (shown) uses the same lighting control units as the MIB-60™ but does not have the PLC / Operator Interface. Instead the MIB-65™ provides two LED indicators to inform the status the lighting system. The MIB-60™ and MIB-65™ are ergonomically designed and implement a patented balanced lighting system that generates an 12 Liter inspection volume in which light intensity is held within ±10%, thus reducing or eliminating inspection data variability. This large inspection volume allows the inspector to easily position samples in the chamber and is ideal for large containers such as IV bags.

The MIB-60™ and MIB-65™ implement a Patented parallel lighting system similar to the MIB-100™. The uniform lighting volume is produced by high output LED panels that use a fixed position on the top and bottom of the enclosure. The light intensity in the MIB-65™ is adjusted with the Master Intensity Control on the front panel. The light intensity in the MIB-60™ implements digital light control and is selected on the operator interface and entered as the desired Lux value. The MIB-60™ incorporates many of the features found in the MIB-100™ but in a smaller package. The MIB-60™ and MIB-65™ have a unique lighting blind system to prevent the inspector from viewing the LED panel surface directly.

The MIB-60™ uses a PLC interfaced to a touch screen display for control of many of the units functions, such as timers for inspector pacing, monitoring the stability of the power supplies, interface to audible and visual alarms and connection to footswitch. Several operational modes can be selected from the operator interface including Indexed Inspections (user input after each step of inspection process), Continuous Inspection (user input after a complete inspection cycle), Data Collection Mode (tally inspection results or not), White / Black Inspection or Monochrome Inspection (18% Gray Card or White Background Only), and many others. There are timers for each step of the inspection cycle that the supervisor is allow change, this is very important for consistent inspection results. The MIB-60™ with PLC and Pacer control has two LED's mounted on the left and right of the background to indicate the valid inspection period. It is suggested that the foot pedal is used with MIB-60 for control of inspection cycle and Pass / Fail selection.