MIB-100 Special Features

The duration of each inspection interval is determined by the length of time

that a particular color appears on the screen and finishes with an audio signal.

The duration for each inspection can be altered in 0.1-second increments by the

supervisor. The operator simply touches a button on the operator interface to

begin the inspection process. The operator interface indicates when the

inspection interval has expired by changing color. At the completion of the

inspection cycle the inspector can record whether the last sample passed or

failed the visual inspection. The PLC will keep the total number of containers

Accepted, Rejected and total number of inspections performed. The supervisor can

reset the data accumulation at the beginning of a new tray, batch or shift.

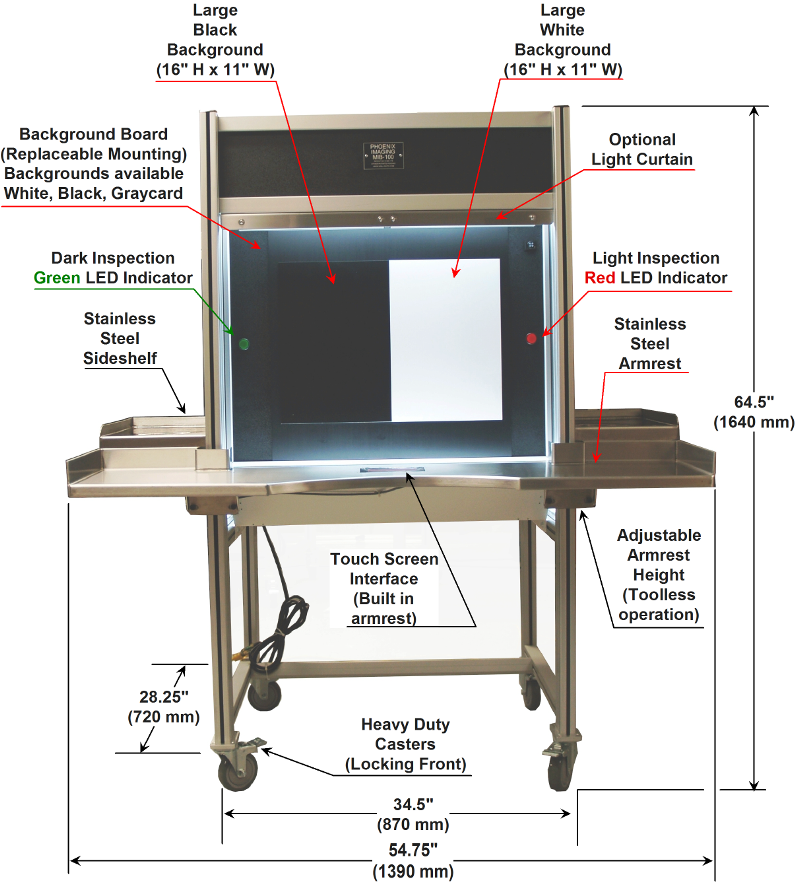

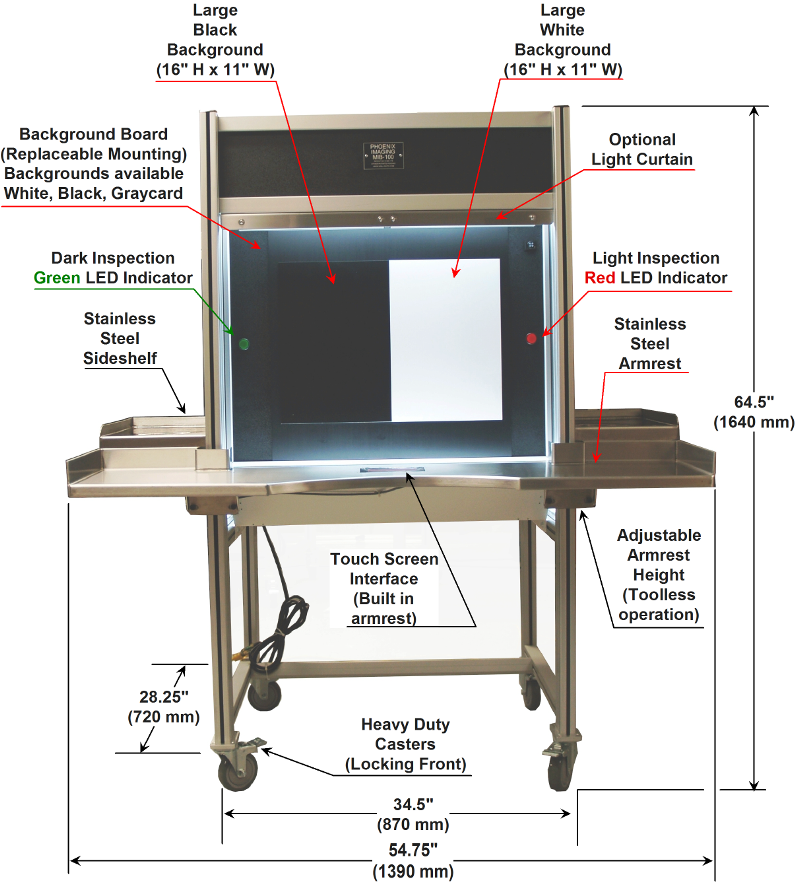

Figure 1. MIB-100DLC Key Components of Production Model

The MIB-100DLC offers the latest design configuration in

the product line. The system is based on the standard MIB-100™ framework

with several unique features. The "D" option refers to a digital control

added to the PLC that allows the user to change the light intensity within the

inspection volume by simply entering desired value on the operator interface.

This feature is useful when inspections mandate different intensity levels for

different products. The user can change from 2000 Lux to 6500 Lux with a

few entries on the keypad. There is an optional "Programming Selector

Switch" mounted behind a locked door to prevent unauthorized light intensity

changes.

The "LC" option refers to the addition of light curtains

in front of the White and Black backgrounds. The LC option will

automatically start the countdown of the PLC Pacer function when the inspection

holds the product in the inspection volume. If the product is removed

prematurely from the inspection volume prior to reaching the zero time of

countdown timer then the inspection cycle must begin again before moving to the

next step of the sequence. The LC option requires that the product be be

positioned in the inspection volumes for the proper durations, thus improving

inspection consistency. This option can be used in combination with the

2-position footswitch to record Pass/Fail count of containers, useful in the

reconciliation of defective units.

The MIB-100™ is fabricated with an anodized aluminum framework and

black

polycarbonate panels. The panels have a dual purpose; first to shroud the

inspection samples from ambient light and second to insure the proper background

is available for the inspection. The electronic components necessary for operation

are included as part of the standard MIB-100™ system

configuration,

including the lighting control systems

(with feedback circuitry), the Operator Interface (visual display), the electronic

pacer system and the LED visual

pacer indicators. The system can be ordered with the standard curved front

Corian© armrest, optional straight front Corian© armrest

or optional curved front stainless steel armrest. The placement of the

Operator Interface can be selected from Left, Center or Right sides of the

armrest.

NOTE: The

lamps selected for MIB-100™ provide approximately

6,000 - 10,000 hours of life1 in

which the intensity maintains an acceptable output level. The standard operating

procedure requires that the lamps be changed at least once a year. Normally the

lamp change is scheduled during the July or December shutdown period.

It should be noted that all lamps provided by Phoenix Imaging are short tested,

burned in for at least 100 hours and then measured to obtain the lamps initial

output intensity and given a unique serial number. When a Phoenix Imaging

Manual Inspection Booth is manufactured all the lamps are matched to specific

output, i.e. foot-candle. The initial lamp output is recorded on the

manufacturing label so that the lamps can be replaced with lamps of the same

output when necessary. This reduces the time required during the

calibration process, often no adjustments are required! Phoenix Imaging

stocks thousands of biax lamps for MIB customers and offer same day shipment if

ordered before 2:00 pm EST.

Available MIB-100™ Options

There are a number of optional components that can be

added to the MIB-100™ to aid the inspector and make the inspection task more

comfortable.

1) The "Visor Kit" offered on MIB-100™ Version 2.3 has

been superseded with the "Top and Bottom Blind" option on MIB-100™ Version 3.1

and above. The Top and Bottom Blind Option prevents the inspector from

direct viewing of the illumination sources or bright interior surfaces when the

lamps are positioned close to the front of the booth. There is minimal

decrease in light intensity in the inspection volume.

Figure 2 - Top and Bottom Blinds

2) The MIB-100™ booth can be raised or lowered by using the booth

hydraulic leveling kit to increase the center line on the inspection area by 12 inches,

helpful when booths are shared with inspectors of different statures. This is an electric assist unit so with the

push of a button will raise or lower the booth to the perfect height for each

inspector! The pump assembly is covered with a stainless steel shroud as

illustrated in Figure 3.

Figure 3 - Hydraulic Leg Lift Option

3) There is an audible alarm option that will provide

audible signals for pacing operations as well as the standard LED pacers.

The audible alarm can be turned on or off in software. There is a volume

control built into the audible alarm to adjust the level.

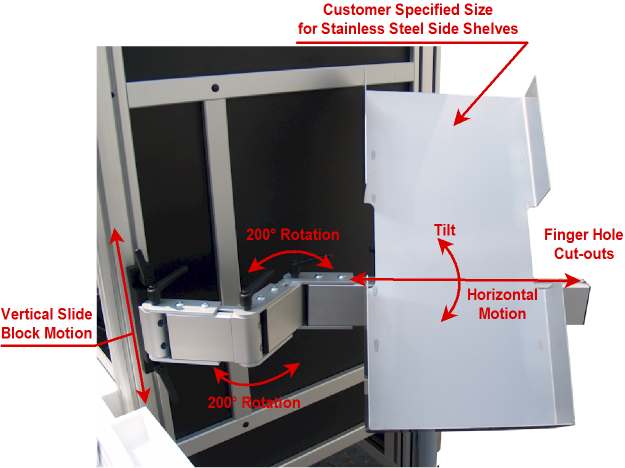

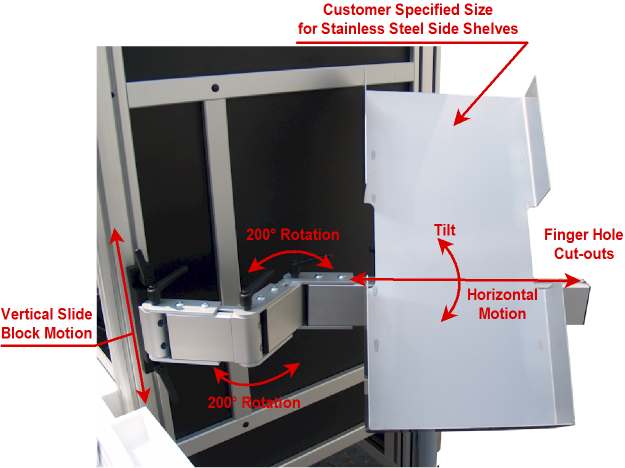

4) The optional Side Shelves Kit is very useful when the

MIB-100™ is used for high volume production work. The optional stainless

steel side shelves for

in-process product flow are

fabricated to hold customer product trays. The side shelves can be ordered

in fully adjustable or fixed configurations. The fully adjustable side

shelves have articulated joints that allow the trays to oriented in the most

comfortable position for the individual inspectors. The arms are articulated

and the joints allow the shelves to be positioned in almost an infinite number

of ways. The side shelves are designed to fit the size of the customer

holding trays.

Figure 4. Adjustable

Stainless Steel Shelf

Figure 4 above illustrates the adjustment handles used to raise/lower and rotate

the shelf support arm. No external tools are required to make the

adjustments. When the handles contact the wall or structure simply lift

them toward the hex head screw and rotate them to a new position.

5) The Plastic Catch Basin is used to protect

the bottom mirror when the operator is inspecting large or heavy containers.

The trays holds 0.5 liters of fluid and will prevent protect from entering the

inspection booth in the event of an accident. The Catch Basin is

constructed of Acrylic plastic for durability and it will not impact the light

intensity. It is easy to clean with soapy water or IPA wipe.

Figure 5 - Plastic Catch Basin to cover lower mirror plate

6) The foot switch option is use to start the inspection

cycle in place of touching the operator screen. It heavy duty construction

of this dual actuator foot switch is designed for millions of cycles.

There is a raise ridge between the two actuators to prevent accidental contact.

The foot switch has a 2 M cable and quick disconnect to the bottom of the booth.

7) New Stainless Steel Armrest is available with or

without Side Shroud Covers! (See Figure 1 for an example of the SS

Armrest).

8) Top Shroud with adjustable speed cooling fans.

This option is useful when the inspection booth will be used in an environment

in which the light is not controlled well. The Top Shroud minimizes the

effects of ambient lighting on the inspection process. To keep the

inspector comfortable there are dual fans with a speed control.

Figure 6 - Top Shroud with Cooling Fans

Illumination System Considerations

ILLUMINANCE: (old term: ILLUMINATION)

Definition: (density of luminous flux on a surface)

Symbol: E

Unit: Footcandle (fc) = (1 lumen per sq. foot)

Unit: Lux (lx) = (1 lumen per sq. meter)

EQUATIONS

Candela

Lamp Lumens

FC = ------------------------

FC = -----------------

Distance

square (ft.)

Area (sq.ft)

Candela

Lamp Lumens

LUX = ------------------------

LUX = ----------------

Distance square

(m.)

Area (sq. m.)

CONVERSIONS

FC = Lux x .0929

LUX = FC x 10.76 - (ie: 550 FC =

5918 LUX)

1 - Lamp life depends on intensity during use.

High intensity inspection requirements will have a shorter lamp life than low

intensity inspection requirements. Nominal use at 3750 Lux will provide

approximately 6,000 hours of use.

|