Manual Inspection Booths (MIB)

Manual Inspection

Solutions for Bio-Tech, Medical Device and Pharmaceutical Customers

Phoenix Imaging Ltd. manufacturers a complete line on

manual inspection booths designed for visual inspection of pharmaceutical

products. The booths are designed with feed back control circuitry to

insure that the light intensity remains at the desired level specified in the

inspection procedure. A wide selection of booth sizes and optical formats

are available to meet specific inspection requirements. There are two

basic light delivery methods in to the inspection volume, the inspection volume

is defined as the volume in which the light intensity remains consistently

within a ±10% range. Generally the inspection volume horizontal center is

considered the division between the Black and White backgrounds. The

vertical center is dependent on the light delivery method on the inspection

booth. The two methods are single-sided and dual-sided lighting.

Most common light booths use the single-sided lighting method where the light

source is positioned above the White / Black inspection background. The

deficiency of this method is that the light intensity varies as a function of

distance from the source and this produces a very narrow inspection volume.

The Dual-sided lighting system has illumination sources on two sides of the

inspection volume, either top/bottom or left/right sides. The inspection

volume is very large in a dual-sided lighting system because a one moves away

from one light source the intensity decreases but the light from the opposite

light sources increases keeping the total intensity approximately the same.

MIB-100D™ with Stainless Steel Armrest and Fixed Side

Shelves

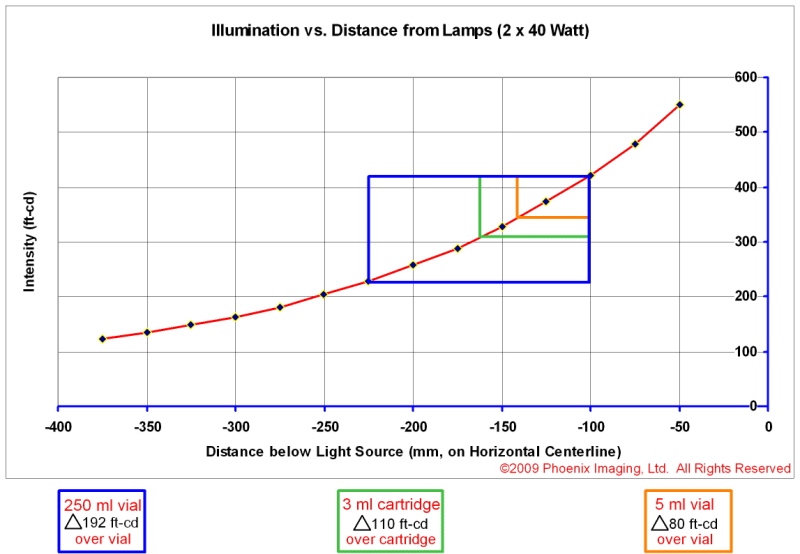

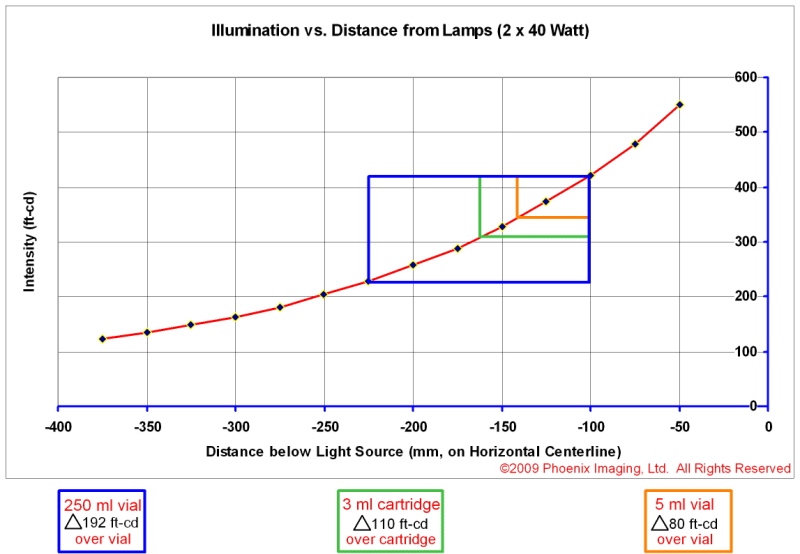

The illustration below show the average Intensity

(ft.-cd.) verses the distance from the light source. Since this is

single-sided light source there is only one distance below the light source

remains constant. The diagram illustrates the variation of light intensity

within a container that is held at a constant distance from the light source.

I should be noted that the change in light intensity will be even worse if the

container experienced a variance in position. The larger the container,

the greater the variation in light intensity. The orange box represents

the size of typical 5 ml glass vial (variation in light intensity is

approximately 80 foot-candles [~860 Lux]). The green box represents a

typical 3 ml cartridge (variation in light intensity is approximately 110

foot-candles [1183 Lux]). The blue box represents a 250 ml vial (variation

in light intensity is approximately 192 foot-candles [2065 Lux]).

Single-sided Light Booth (Light Intensity vs. Distance

from Source)

Why is it important to maintain a constant light intensity

while performing the visual inspection? Because the apparent size of a

contaminating particle and therefore the probability of rejection is directly

proportional to the intensity of the light used in the inspection process.

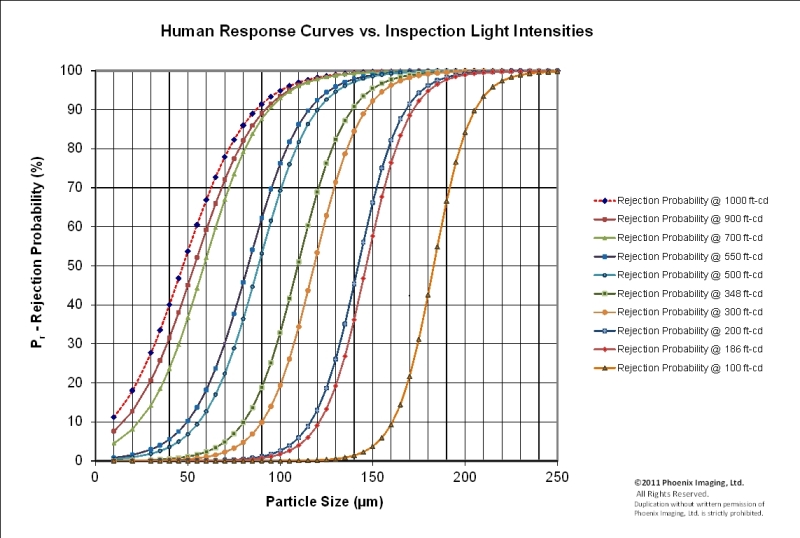

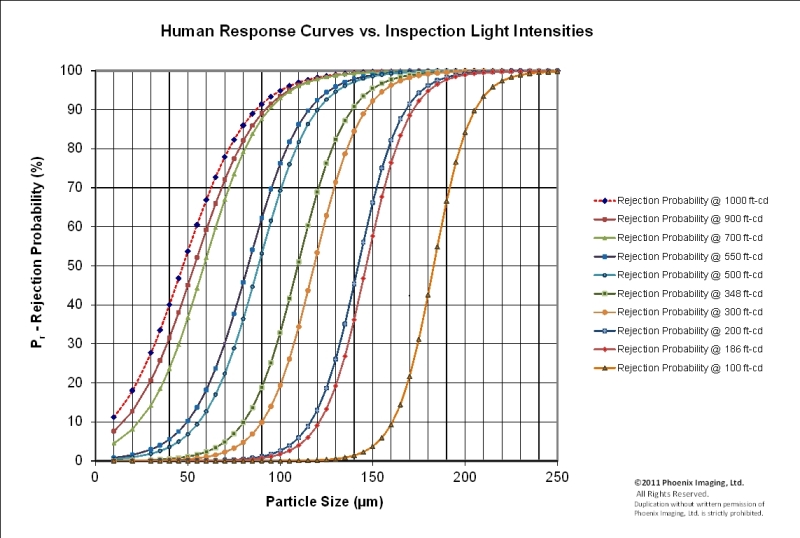

If one were to examine the Human Response Curve (HRC) for a given intensity of

light in the inspection volume, the effect of the afore mentioned light

variations on the Probability of Rejection (PR) becomes

obvious. The HRC at various light intensities (ft.-cd.) illustrate the

change in Probability of Rejection. For example, a 122µm diameter particle

with a 70% Probability of Rejection with 348 ft.-cd. (3750 Lux) only has a 54%

Probability of Rejection with 300 ft.-cd. (3228 Lux).

This is less than the height of the 5ml vial!

Phoenix Imaging Human Response Curves at Multiple Light

Intensities

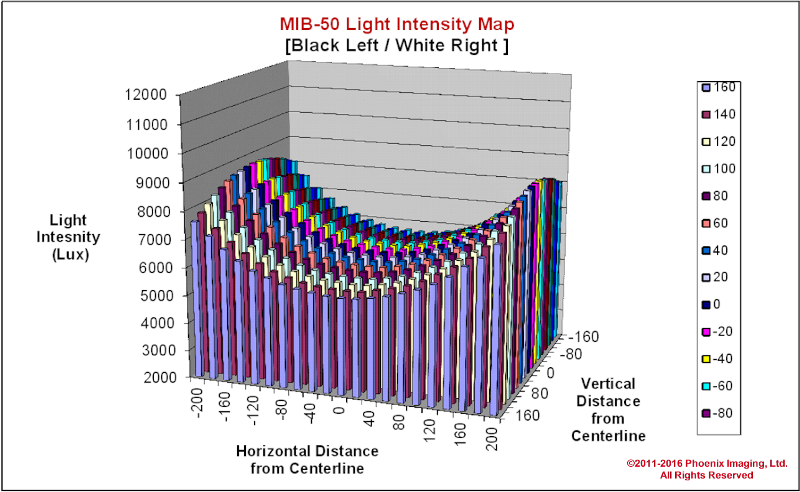

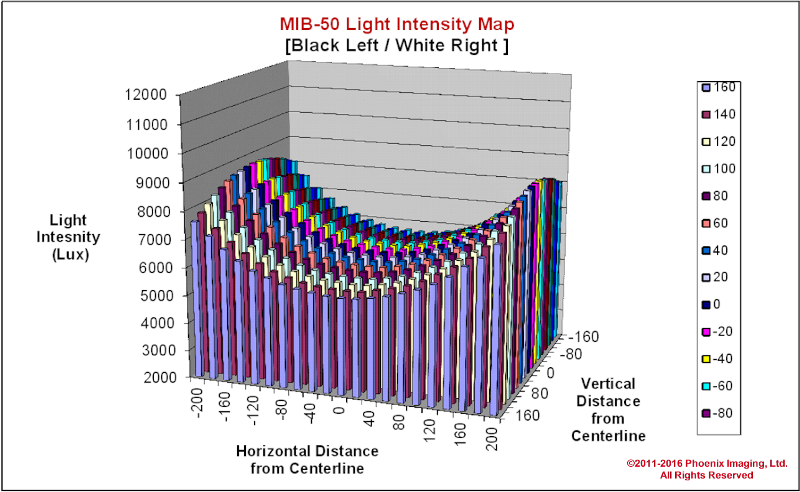

The importance of the "uniform" inspection volume is

critical if consistent inspection results as measured by the Probability of

Rejection (PR) are desired. The effectiveness of human

inspection for contaminating particles can be improved upon greatly by a large

uniform inspection volume. The best method to achieve a uniform inspection

volume is to use dual-sided lighting. The figure below illustrates the

uniformity of the MIB-50™ light booth. Instead of the typical "waterfall"

illumination of a single-sided lighting system the MIB-50™ provides a saddle

with a flat region in the center of the booth. The saddle rises on the

left and right sides because the light enter the booth from those directions.

Other Phoenix Imaging booths have light that enters the inspection volume from

the top / bottom directions. Regardless of the direction in which light

enter the MIB booth a large uniform lighting region is produced.

Phoenix Imaging MIB-50™ Light Intensity Map

Determine the MIB Product that best meets your

requirements, see the MIB Selection Chart

|