ParticleScope™ - Particle

Measurement System

Phoenix Imaging, Ltd. has released a new website dedicated

to Bio-Pharma, Healthcare and Pharmaceutical

related products and services at

www.mib-lights.com. Please visit this site for the latest information

regarding

RLPS™, MIB and ParticleScope™ products.

Patented Non-Destructive Particle Detection and

Measurement System used for Parential (SVI) Products.

Phoenix Imaging releases a new product for the detection

and measurement of small contamination particles in small vial for injection (SVI).

The ParticleScope™

instrument is unique in its approach for the isolation of suspect contamination

particles in the solution. Unlike many of the automated inspection systems

that were previously sold, the ParticleScope™ instrument utilizes multiple high

resolution images that are acquired from simultaneous sensors. The typical

inspection will acquire as many as 50 images from each of the sensors. Two

sensor resolutions are available for the system, 2 mega-pixel or 5 mega-pixel.

The 2 mega-pixel system can resolve 50µm diameter particles while the 5

mega-pixel sensor can resolve <25µm particles. The system is the only

Particle Detection and Measurement system that provides NIST traceable measurements of the contaminating particle size. The inspection system is

designed as as small bench top unit that is totally self-contained (except for

wireless keyboard and mouse).

The ParticleScope™ instrument is designed to perform

non-destructive testing on one sample at a time. The sample can be either

a small vial (1ml to 20 ml), a Cartridge or a Syringe. The system options

include precise measurement of a single particle or measurement of multiple

particles to determine the size distribution for each image frame. This

system will detect a contaminating particle 100% of the time. The

determination of actual particle size requires that minimum number of frames

with the same aspect ratio particle be isolated. If the particle is

isolated and measured in the minimum number of frames the "particle size" is

reported.

The ParticleScope™ instrument has already been issued

several patents with others patents pending. This technology has been

under development for over 10 years before the first release of the instrument.

The instrument is available now in Version 1.2 running under the Windows® 7

environment. The system is self contained and only requires 120VAC power

for operation.

The unique cube lighting system implements over 1,000

LED's that provide directional illumination on demand. The wavelength of

the LED's are optimized for the CCD sensor's. The inspection system

Patented angle of image acquisition insures that even the heaviest particles

that settle on the floor of the container will be detected and measured.

The second sensor inspects the fill fluid all the way to the meniscus.

Both of these areas are often ignored by other inspection technologies.

All of the inspection parameters are available for

modification by the user, provided that they have the proper security level and

permission to alter inspection parameters. The software is part 11

compliant and permanently records all changes is a edit log. Once a test

has been run the results and test parameters can not be altered. The

inspection of a specific product will be defined by the "Velocity Motion

Profile" or VMF. The VMF defines the acceleration, maximum velocity,

duration and deceleration rate of the container to properly agitate the fluid in

the container. The VMF depends on the container size, shape, fill volume,

fluid viscosity and temperature of the fluid. Each can have a unique VMF

associated with the testing procedure. In addition each test may have more

than one VMF. In most cases at least two VMF's are used for the

inspection, one for low density particle detection and one for high density

particle detection. This system allows you to discover the best testing

properties.

The inspection results are available for review in both .csv

and Microsoft® Access database formats. There are two files associated

with each inspection result, a "Summary" file and "Detail" file. The

summary provides a single line of results for each container inspected in a Lot.

The detail files provide the results of each individual inspection frame.

Information contained in "Summary" result files include:

|

Product / Test Description |

sample # |

max blobs |

Avg of max blobs |

min Blob

size µm |

min Blob aspect Ratio |

min Blob occup Ratio |

max Blob size µm |

max Blob aspect Ratio |

max Blob occup Ratio |

Frames with 5+ particles |

Frames with 4 particles |

Frames with 3 particles |

Frames with 2 particles |

1 p's |

0 p's |

n frames |

in frame #(s)[phase] |

This system provides a wealth of information about the

samples being tested. In addition the system provides the most consistent

detection and measurement results of any non-destructive inspection technology

SVI containers.

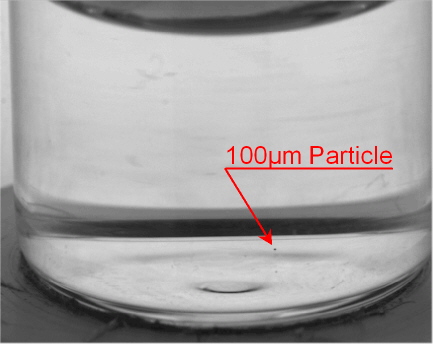

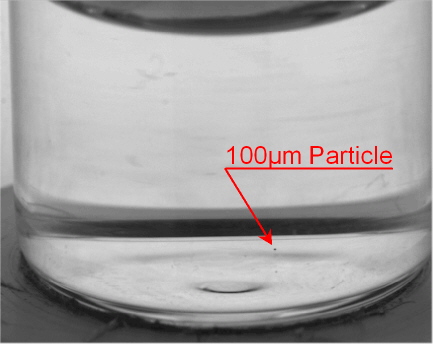

The image at the right illustrates a typical image that is

acquired with the 2 mega-pixel sensor. The 100µm diameter particle is

clearly visible as is the reflection of the particle just below it. The

ParticleScope™ system is intelligent enough to ignore multiple particles that

have the same trajectory or path in the solution and only count the real

particle. The system can detect much smaller particles that the minimum

measurement size. However, measurement is limited to particles that are

larger than a minimum pixel area. The instrument measures particles using

two different measurement techniques, each of which have their own calibration

curves associated with them. The most common technique is the binary

representation of the particle is good for detection if a sufficient number

inspection frames are acquired (typically 10 or more). The more precise

method of measurement implements our patented "Grayscale Summation" technique

that integrates all of the gray values in the particle after image

normalization. The error bars are approximately one-third the width of the

binary measurement. The results can only be achieved using a minimum 2

mega-pixel sensor but are much better with the larger 5 mega-pixel sensor.

The ParticleScope™

instrument has many uses but high on the application list are non-subjective

inspection of Lot samples, testing of formulations by particle size

distribution, determining the efficiency and aiding with the validation of high

speed automated inspection equipment. Give us a call and we can discuss

your application to see if the ParticleScope™ is the correct instrument for your

project.

A typical 100µm particle as shown in the image to the

right will be approximately 100 pixels in size.

|