Front Cover Porosity Application Profile

As an OEM supplier to Chyrsler, Diversified

Machining (Howell, MI. recently purchased a part of a three plant deal from

UniBoring, Inc.), is a company adept at specialized precision machining,

assembly and inspection of powertrain products. To provide its customers with

quality, high-performance, and competitive products, Diversified precision

machines and assembles intake manifolds, cylinder heads, bedplates, covers and

engine blocks as well as partial and full engine assembly for niche and

production markets.

One of the high volume parts supplied to DaimlerChyrsler is

the Engine Front Timing Chain Case covers for both the 3.7L and 4.7L models.

These Engines are installed into DaimlerChrysler’s Jeep and Dodge vehicles at

seven Assembly Plants worldwide. To ensure the integrity of this part each

surface must be carefully examined for all cast and machined, deformities and

sealing face porosity defects. For this to be accomplished, they contracted

Phoenix Imaging (Livonia, MI; www.phoeniximaging.com) to develop a custom-built

image processing system.

The company implemented Phoenix

Imaging’s AVIS (automated visual inspection system) to perform multiple

operations including porosity inspection, presence of clear and/or tapped holes,

robot guidance and optical character recognition (OCR) for component

traceability. “Moving these inspection tasks from Human vision to robust

Machine Vision ensures defects won’t reach our Customers while providing

traceability into the Vehicle” says John Wagnitz, Quality & Manufacturing

Systems Mgr. The system inspects the front cover on a vertical pallet

conveyor. By holding the front cover in a vertical orientation both sides and

all features can be viewed at the same time.

“To perform an accurate inspection of the part,” says

Gerald Budd, President of Phoenix Imaging, “it is necessary to create software

that encompassed all of the desired inspection task. The task required porosity

inspection of the “A” and “D” faces, non clean up on all machined surfaces,

casting variations, presence of all through holes, presence of tapped holes and

traceability of every inspected component by means of optical character

recognition of indent marker serial number.

The application required multiple sensors of various pixel

resolutions. When initially developed the resolution of CCD sensors were large,

1300 x 1030 x 10-bit CV-M4+ Camera Link cameras from JAI Pulnix. This is small

when compared to the sensor sizes that are implemented in similar applications

of today. However, this technology established the standard for on-line

porosity inspection and demonstrated its use in a real world production

environment.

The application implemented a number of new technologies

created by Phoenix Imaging, several of which are patent pending. Every

successful vision application requires a well designed illumination system.

This is even more critical for surface inspection applications. Phoenix Imaging

manufactures over 300 different types of illumination systems.

We have designed a special illumination system that

could be implemented on-line and provide uniform illumination for viewing the

machined surfaces of the front cover. One of the most

difficult problems to overcome using such a system is to reduce the false

rejects due to surface contamination or machining operations. Phoenix

Imaging has developed a unique illumination system that reduces information from

surface anomalies.

The sensors are interfaced to the

company’s PC-based PVS-100 machine vision system using two CL1 frame grabbers

from Epix (Buffalo Grove, IL). The machined features of the component, i.e.

quality of irregular shaped surfaces, holes, and threads are inspected using

specific vision algorithms. The vision algorithms are created using the

company’s VisionMaker™ software. The software allows each of the inspection

algorithms to be developed and tested very quickly. The VisionMaker™ software

acts as a pre-filter to all of the company’s ACTIVE-X vision tools. The

software allows the vision developer to construct the vision algorithm as a list

of low level vision functions arranged to massage the image and prepare it

before being analyzed by the ACTIVE-X tool. Unlike many vision products, there

is no need to compile the vision algorithm before implementation. This allows

the vision developer (or trained user) to modify a vision algorithm in the

production environment without special computers, development tools or

libraries. According to Budd “VisionMaker™ allows us to generate and test

vision algorithms in minutes rather than hours.”

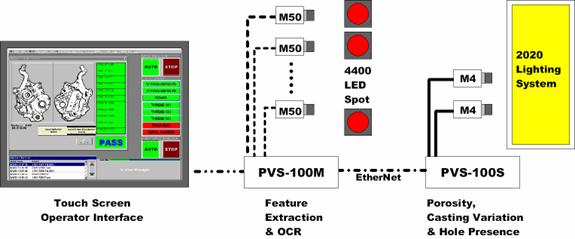

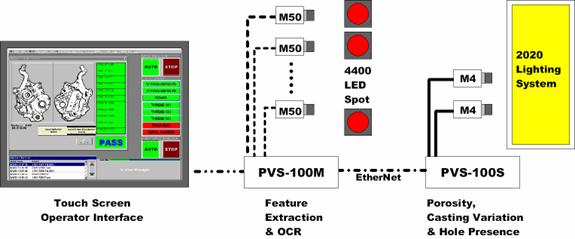

Figure 1. Complete AVIS Installation

Figure 1 shows the components

used in the Automated Visual Inspection System (AVIS) used by Diversified for

the DaimlerChyrsler 3.7 / 4.7 L Front Cover inspection. The main electrical

panel sits to the left with a large touch screen operator interface. The main

inspection enclosure housing sensors and lighting system is shown at the right.

The Front Covers are held in pallets and translate through the opening in the

middle of the inspection enclosure. A stack of checked parts appear at the

extreme right waiting robot pickup for placement is air decay leak testers.

The front covers move through the inspection system on a

pallet conveyor system. The inspection system acquires images of both sides of

the front cover simultaneously while being held on a transfer pallet. The

software first locates the position of the component within the field of view of

each sensor. It is important to compensate for both component translation and

rotation because the pallet may experience ware and tear during normal use.

After components are located, a number of inspection zones may be applied to

specific regions. Each inspection zone can apply its unique inspection

criteria. The inspection system can perform tasks that human inspectors find

difficult, including the ability to accurately measure the size of

imperfections, count the total number of imperfections, determine the density of

imperfections per unit area, and determine the proximity of imperfections with

respect to each other.

Using the M4 medium resolution cameras, it was possible to

check for porosity defects of <1mm with a field of view of about 400 mm x 400

mm. The large format or high resolution cameras

allow the machine vision engineer to use one camera in the place of four or more

cameras simplifying both system setup and calculations. The resolution of a

machine vision system can be determined by the ratio of the number of pixels in

the sensor to the field of view (FOV). Cameras with a pixel resolution of 1300

x 1030 to 2000 x 1600 are considered as medium resolution formats. Cameras with

a pixel resolution of 3000 x 2000 or greater are currently considered to be a

high-resolution format. Budd further states that the latest generation system

has demonstrated the ability to detect porosity < 400µm on a 500 mm long

automotive component using an 8 mega-pixel camera. There are even larger format

cameras in the development pipeline.

In order to perform the inspection of features in other

regions of the casting six (6) 752 x 582 x 8-bit CV-M50 low-resolution (Pulnix-JAI)

cameras are used. The low-resolution cameras were interfaced to second PVS-100M

using three (3) SV5 frame grabbers from Epix. The inspection system is designed

using a modular format in which one image processor acts as the “Cell Master”

and additional image processors serve as “Slave” devices. The image processors

communicate with each other using a high-speed Ethernet link, 100MB/s or 1

GB/s. Figure 2 below illustrates the basic system configuration for

multi-processor inspection system.

Figure 2. Basic System Configuration

The main program is called the Automated Visual Inspection

System (AVIS). AVIS acts as the main nerve center of the inspection system. All

inspection parameters, tolerance limits, and results are displayed through

AVIS. The operator interface is generated using Microsoft Visual Studio,

usually programmed in VisualBasic. The VisualBasic environment is preferred

because it allows us to rapidly customize screens to meet specific customer

requirements.

The actual inspection process starts on a “Viewport”, this

is a screen that displays the image as acquired from an individual sensor. Each

sensor requires at least one Viewport on which the live or processed images are

displayed. The image processing tools used to perform the actual inspection

tasks are provided in an ACTIVE-X format. The specific tools required for each

task may be added by simply dragging and dropping them on the Viewport. The

ACTIVE-X toolset includes utilities for alignment, blob characteristics, curve

fitting, etc., that permit the developer to select the functions that can be

used individually or together to measure the specific features of a component.

In this application the Phoenix Imaging team developed a system that could be

used to classify specific defects in a number of zones, each with a specific set

of requirements.

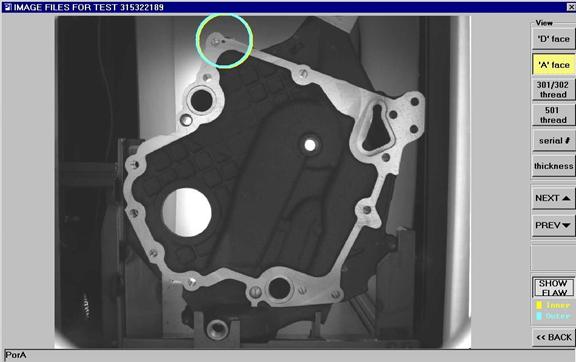

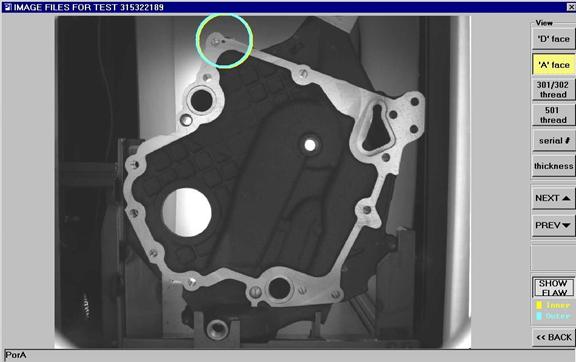

Figure 3. Screen shot highlighting the suspect area that failed inspection

Figure 3 is representative of an example log file of a

component that failed one of the inspections. The file is labeled with the

serial number of the component and indicate the type and location of flaws by

drawing a circle around the defect location. This method was selected so that

the defect was obscured by graphics and the image could be examined at a later

time. Every front cover has a serial number indent marked on the neck in the

machining process. The mark is positioned so that it can be identified in “Car

Position” and read by the OCR software during the inspection process. Every

image acquired by the inspection is archived on DVD using the serial number.

The archive database includes images of “Accepted” and “Rejected” components.

The database can be used to verify the condition of an individual product as

tested just prior to shipment to the customer. The technology developed for

this project has demonstrated unique inspection and traceability capabilities

and is patent pending.

A typical system

with a cost between $200k

and $400k can pay for itself

in less than a year. When you consider the cost

of onsite sorting after a suspect products enters the production stream

costs associated with such as system become

immediately justifiable. Human inspection has been

shown to be about 70% effective at best, an online AVSIS™ will provide

consistent inspection capability and will never require a break.

|