Surface Inspection Systems

Phoenix Imaging has specific expertise in surface

inspection applications. Surface Inspection refers to isolation of

features on a surface that are not common with component structure.

Surface imperfections are referred to by many names, the most common names

attributed to the these are: scratches, dents, dings, surface roughness,

porosity, abrasions, pits, blisters, etc.. Whether the surface

imperfection appears on glass, plastic, stamped metal components, precision cast

components, machined metal components, or other substrates a Surface Inspection

System can be designed to isolate and measure them. There are several

common techniques often employed in the design and manufacture of the surface

inspection system but it is important to match the correct technology to

application in order to achieve optimum performance. This is where Phoenix

Imaging can assist you with providing the correct solution, we are the

Surface Inspection Experts!

Porosity Inspection Systems

Porosity Inspection on Machined Metal Components

Porosity

inspection on machined metal components, primarily aluminum and precision

die-cast magnesium castings represents one of the most important uses of the

Phoenix Imaging AVSIS™ automated inspection systems. AVSIS™ (Automated

Visual Surface Inspection System) has been in use finding surface imperfections

since 2001. The AVSIS™ technology has undergone multiple design changes in

the area image acquisition and image processing hardware to increase resolution

and processing speed. The underlining image processing algorithms remain

steadfast industrial trade secrets. Unlike other technologies that claim

to have the ability to perform porosity inspection the AVSIS™ technology works

and works extremely well. The system has be implemented to isolate surface

imperfections as small as 10µm in diameter and with sensor resolutions as small

as 1µm per pixel. Not all applications need that resolution in order to be

functional, in fact most customers do not need or want to isolate suspect

regions of that size.

When

cast components are machined, the fresh cut often exposes sub-surface porosity

that can affect the performance of bearing or sealing surfaces. Phoenix Imaging

has developed and patented several technologies to perform this inspection task

effectively at a reasonable cost to the customer. The applications are

successful because they do not rely of simple image thresholding techniques for

the isolation of defects. Manufactures understand that materials may

exhibit variations in color or appearance and that these variations do not

necessarily mean that the component is not acceptable. Our technology

minimizes "false rejects" and continuous system tuning.

Front Cover Non-Clean Up and Porosity Inspection (See

Porosity Profile 1 for additional information)

In-line inspection at 23 second cycle time, both side of

front cover.

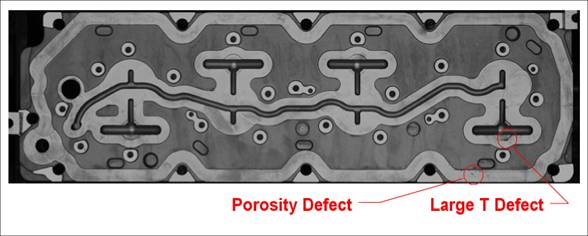

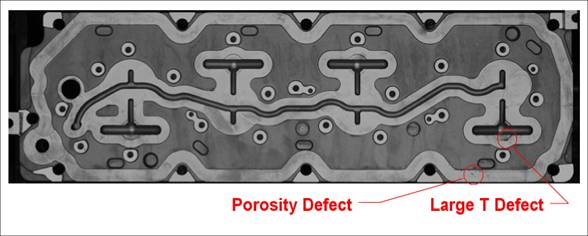

Cylinder Deactivation Plate (See Porosity Profile 2 for

additional information)

Locate component using B&C Datum, position multiple

inspection zones each with different inspection criteria.

Cylinder Deactivation Control

Plate

We have performed surface inspection on a wide range

components and would be happy to evaluate your component using a reduced scale

version of the technology.

Other examples of surface inspection for isolation of

abnormalities.

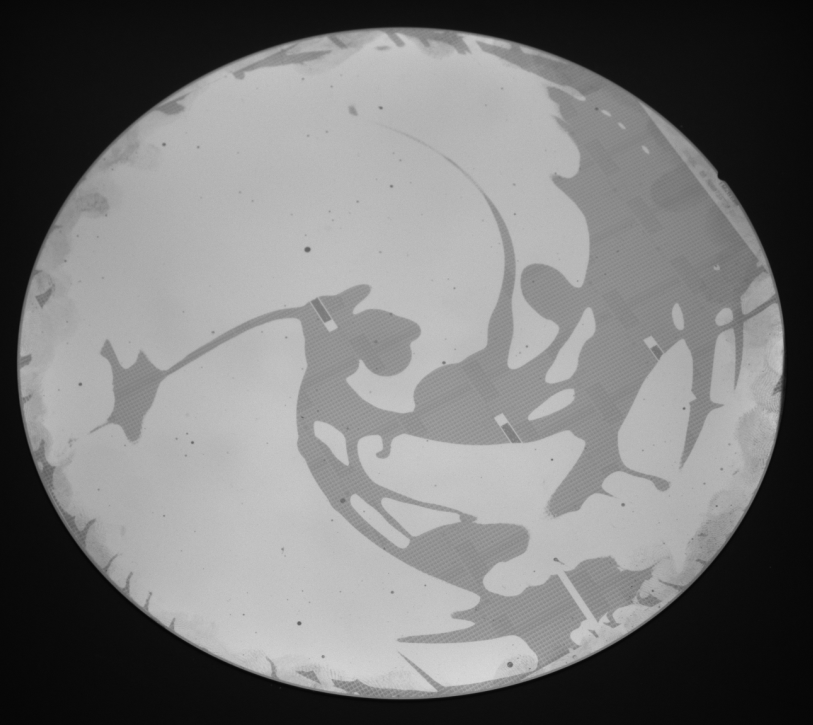

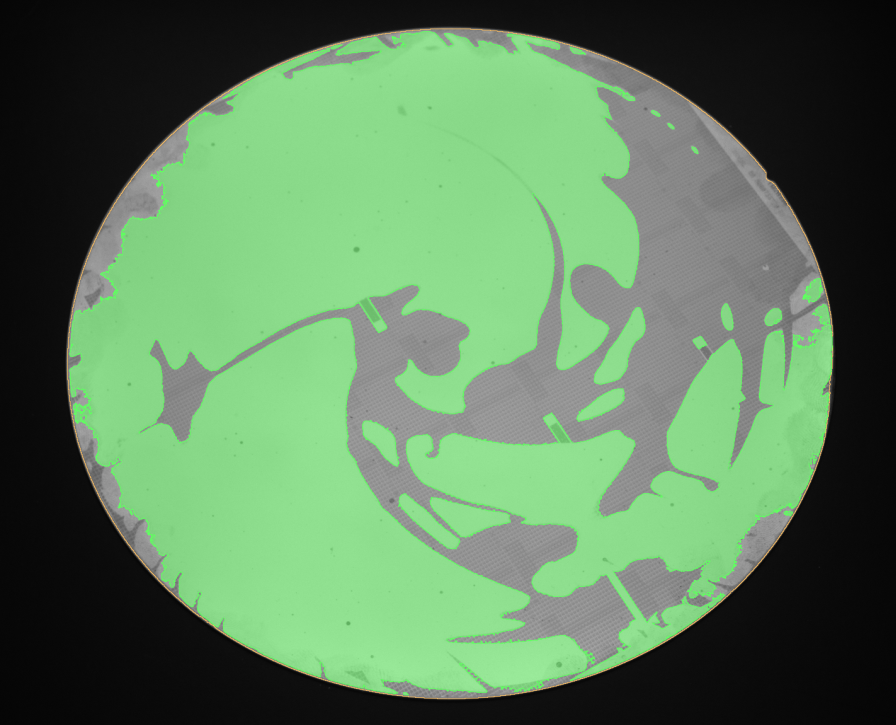

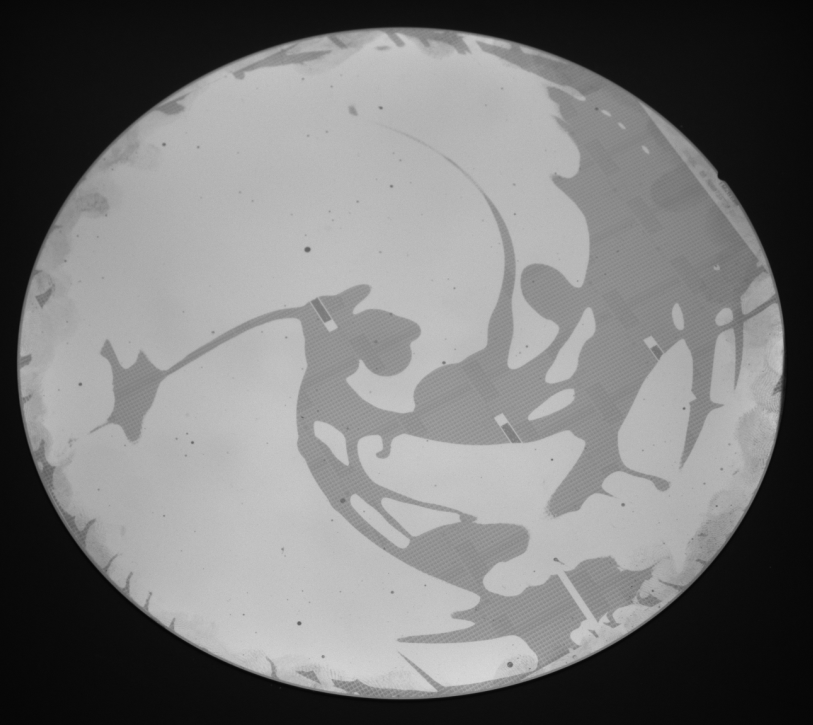

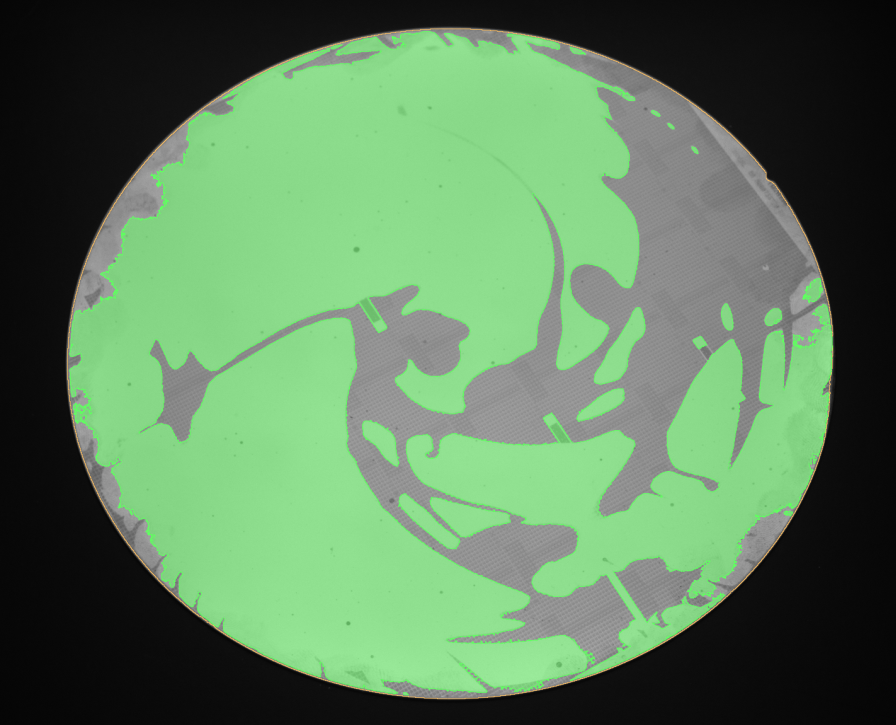

Silicon Wafer

with Dye Mask

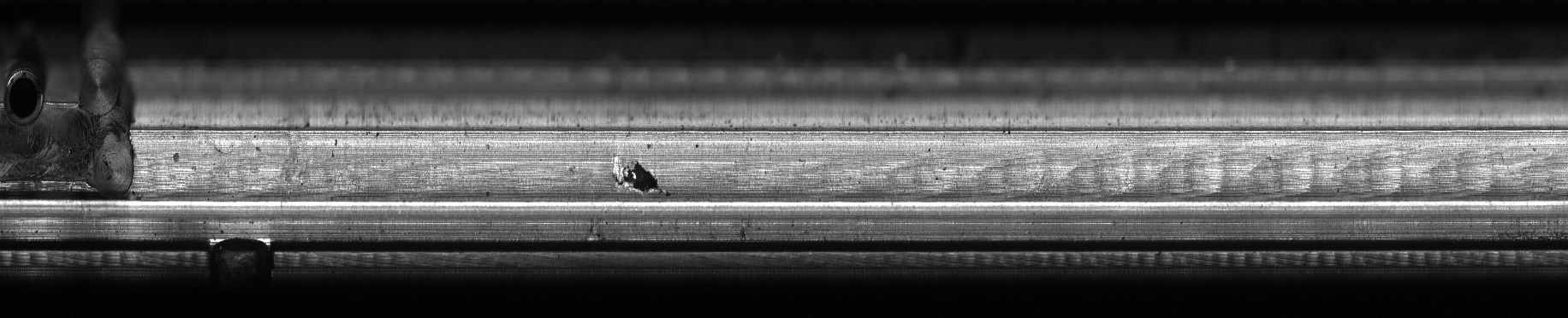

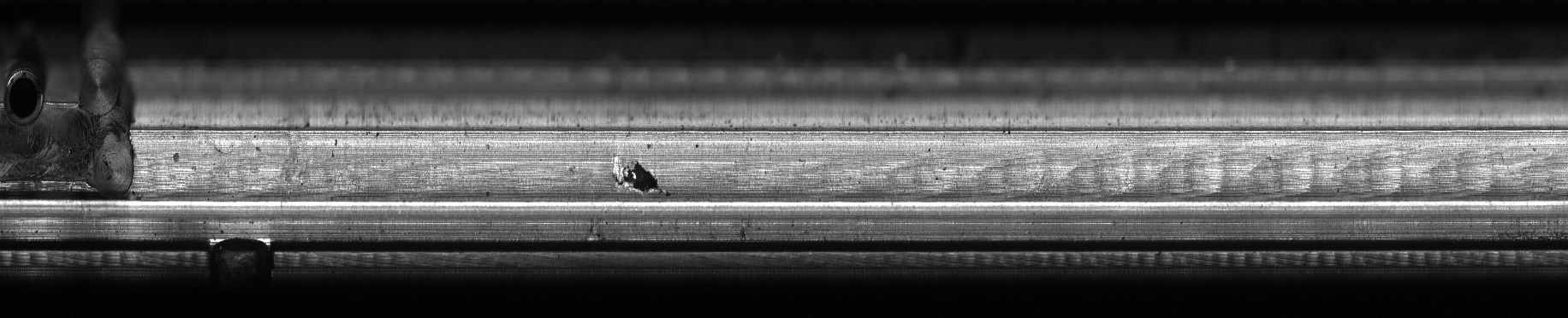

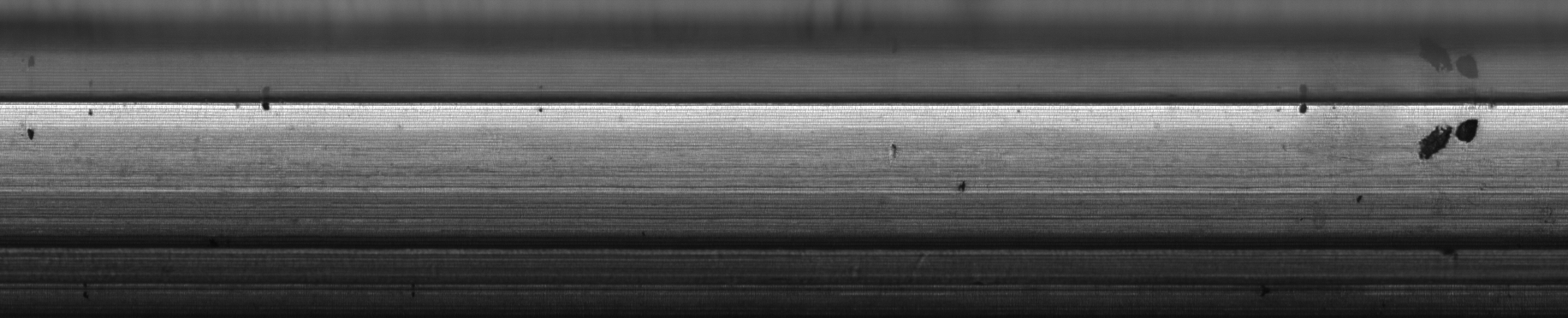

Inside Wall

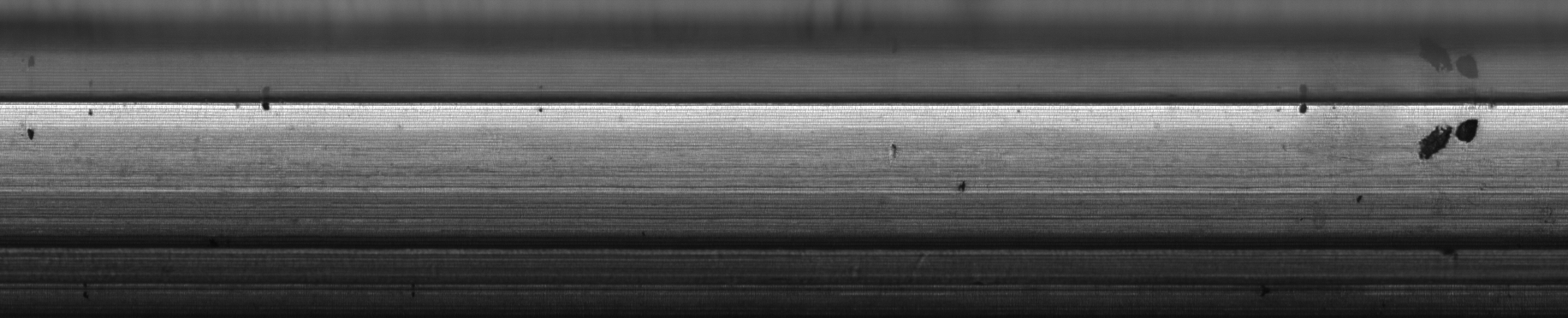

Transmission Component (Porosity and Tool Chatter)

Inside Wall of

Transmission Component = Porosity on Right End of Image (Larger 440

µm and 205 µm Proximal Length)

|