|

Phoenix Imaging is a provider of machine vision

systems, machine vision components, image

processing computers, compact machine vision systems, machine

vision software and

integrated turn-key solutions for industrial applications.

Phoenix Imaging is based in the Livonia, Michigan (Western

Suburbs of Detroit) and has been servicing the United States and Ontario.

Phoenix Imaging has agreed to an

industry Code of Ethics and has access to the most up to date information

available, including professional certification, training and continuing

education; state of the art technology; technical services; industry trends and

statistical data; and research and development.

The company has expertise

in wide range of machine vision technologies, with specializations in:

-

Stand-alone Machine Vision

Inspection Systems,

-

Surface

Inspection and Flaw Detection Systems (AVSIS™),

-

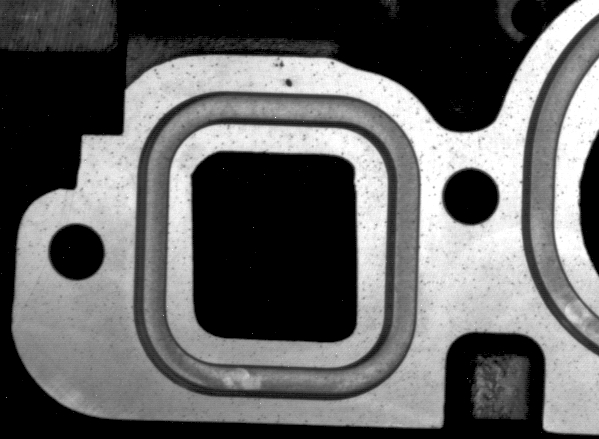

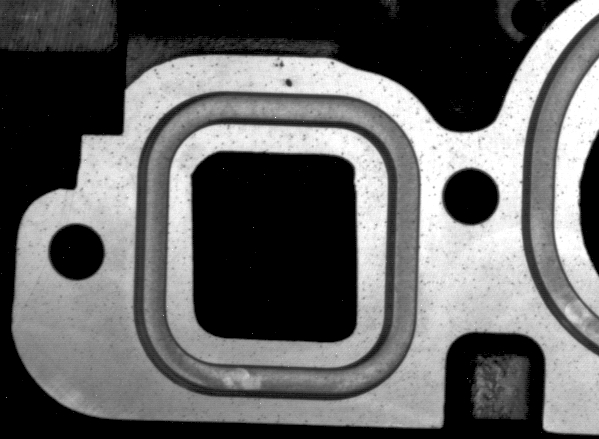

Porosity

detection (and surface blemishes) inside and on surface of machined components (AVSIS™),

-

On-line Non-contact

Dimension

Measurement systems (VCMM) provides accurate measures and low GR&R,

-

Assembly Verification systems (monochrome and color)

or component configuration,

-

Wore and Broken Tool Status

Advisor Systems (CNC-TSA™),

-

Infrared (IR)

Inspection systems,

-

Optical Character

Recognition (OCR / OCV) systems.

-

Advanced Integrated Robotic

Inspection Systems.

-

Integrated Laser Mark

Traceability / Inspection Systems.

Phoenix Imaging's highly skilled team

of vision engineers provide a non-biased appraisal of machine vision

applications. The team can draw on expertise from simple integrated smart

sensors to highly complex multiple format sensor inspection systems. The

company provides consultation solution to determine if a viable solution is at

hand or if new technology is required. Phoenix Imaging has worked with

100's of companies in the development of machine vision algorithms, low level

vision tools, and basic physics to engineer front-end optical solutions.

Phoenix Imaging has been designing and

fabricating illumination systems for machine vision projects since the early

1990's. The lighting system include High Frequency Fluorescent (both open

and closed loop control, over 300 different models available), extremely uniform

LED back lighting system (3 series), LED spotlights (3 series), precision

control light sources for challenging vision applications. Patented

illuminations systems for large format flat components, Ceramic Tile / Glass

Inspection Chambers, world class manual inspection environments and custom lighting systems for unique customer applications.

Our LED Backlights generate extremely flat illumination fields and are used by

system integration companies and end-users worldwide.

The

company offers machine vision integration services for all of the products and

services that

the company offers including: sensors, lenses, lighting products, image

processors, and hardened inspection system for the industrial environment. Products and services are

available to a wide customer base which includes: original equipment manufacturers, system

integrators, machine builders and end-users. Phoenix Imaging offers a wide

selection of machine vision systems from the low-cost compact vision sensor to

complex image processing systems

utilizing multiple high-resolution

mega-pixel sensors.

Machine vision systems can be purchased as complete turnkey solutions,

partial assemblies or as machine vision components. The machine vision

integration services are available for complete automatic inspection systems or

retro-fit to existing manufacturing lines. The machine vision equipment

can be installed for on-line inspections or off-line inspection. Special

application packages for machine vision systems used in the areas of surface

inspection, seal inspection, porosity, tapped hole, true position, precision

dimension checks and assembly verification.

---

Surface Inspection Systems

and

Porosity Inspection Systems

---

Unique Patented

Technology

is ideal for Surface Inspection Projects!

Phoenix Imaging has

received a US Patent for

Advanced Surface Inspection Technology for the Detection of Porosity and Surface

Imperfections on Machined Metal Surfaces.

Because the

technology is unique, Phoenix Imaging has been issued US Patent

protection ( US 7,394,530).

The technology implements a unique illumination technique that reduces the

effects of surface texture created by the machining process but enhances the

surface abnormalities. This technology is extremely useful in the detection of

porosity that is often found on machined aluminum components.

The technology allows the customer to

assign multiple inspection zones on a surface and apply a separate inspection

criteria to each of them. The inspection zones are aligned to each new

component using manufacturing datum. In addition the technology allows the

customer to measure the dimensions of key feature and measure the position of

the features with respect to the datum. Phoenix Imaging refers to this new

technology as VCMM or “Virtual Coordinate Measurement Machine”.

This technology is not meant to replace existing CMM equipment because it is

designed to measure key feature on components in an on-line mode of operation.

This requires that the features to be inspected must be taught prior to use.

This may require fixtures and specific lighting conditions for the inspection.

What the technology does provide is the ability to inspect 100% of your

components for surface imperfections and the true position of key features with

respect to one or more datum.

Surface inspection of machined metal

components often expose porosity that lies beneath the surface in the casting.

Once exposed the porosity can affect the sealing surface integrity and impact

warranty cost. Phoenix Imaging has developed a range of porosity and

surface inspection systems to identify these defects so that manufacturing can

contain defective products before they reach the customer.

Phoenix Imaging offers a turn-key

inspection package using unique inspection modules developed explicitly for

surface inspection. The patent pending inspection methodology allows the

customer to define multiple inspection zones each with a different set of

inspection criteria. Automatic alignment tools insure that the inspection

is performed correctly even if the component is not located in the proper

position. The inspection algorithms isolate, measure, count, determine

defect density and proximity. With the proper access level the customer

can make adjustments to the inspection parameters using the human machine

interface (HMI).

Each system is designed to meet the

requirements of each customer for porosity measurement, component size and cycle

time. In-line and off-line inspection system have been implemented to

accommodate the customer work flow.

Tell

me more about porosity inspection technology!

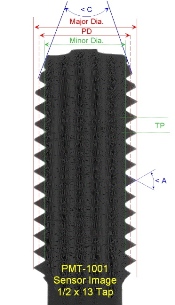

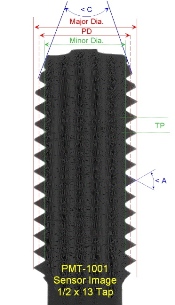

Patented

Machine Vision based

Broken Tool Detection System

TOOL STATUS ADVISOR (CNC-TSA™)

US Patent 7,266,420 for a Machine Vision System

for detection & measurement of CNC machine tools

and

and

[ Tool Inspection in Production ]

[ Master Tool Setup and Receiving Inspection ]

Phoenix Imaging has announced the release

of the new Machine Vision

System used for inspection of CNC cutting tools inside the

machining centers and for checking receiving inventory. The product learns the shape

of new cutting tools and measures the change in the profile. This

technology allows manufactures of high value component to capture defective

conditions as soon as they occur and prevents the manufacture of subsequent

defective components!

The product can be retrofit into existing CNC machining

centers or checking the shape of tools as they are received in to inventory.

The system is called the Tool Status Advisor and it is available in

several configurations. The MET-TSA™ is used to teach the

characteristics of a new tool and the CNC-TSA™ is used to

determine the degree of wear on production tools.

The

typical system is based on the PVS-80 vision controller,

with one or more vision sensors (mounted inside environmental enclosures), and one or

more corresponding LED lighting units. Backlighting is used for tool

silhouette and ring lighting is used to highlight leading edge imperfection when

viewed down the tool axis. The PVS-80 is

pre-mounted inside a NEMA type-4 (IP65) electrical enclosure and is available

with a 15" TFT flat panel touch screen display for parameter adjustment and

inspection information. The system can accommodate direct inputs and outputs

for communication of inspection conditions to external devices. The Standard configuration

provides 8 inputs and 8 outputs connected through industrial standard optical

isolated relay modules. A special version PVS-85 is designed for OEM

customers that would like to mount the image processor inside their own

electrical enclosures. The

typical system is based on the PVS-80 vision controller,

with one or more vision sensors (mounted inside environmental enclosures), and one or

more corresponding LED lighting units. Backlighting is used for tool

silhouette and ring lighting is used to highlight leading edge imperfection when

viewed down the tool axis. The PVS-80 is

pre-mounted inside a NEMA type-4 (IP65) electrical enclosure and is available

with a 15" TFT flat panel touch screen display for parameter adjustment and

inspection information. The system can accommodate direct inputs and outputs

for communication of inspection conditions to external devices. The Standard configuration

provides 8 inputs and 8 outputs connected through industrial standard optical

isolated relay modules. A special version PVS-85 is designed for OEM

customers that would like to mount the image processor inside their own

electrical enclosures.

Perhaps the most versatile feature on the MET-TSA™ is that it allows the user to

easily create master images of tooling

for comparison of new tools as they are replaced in tool holders. Unlike many

other tool detection technologies the CNC-TSA™ can find wore or partially broken

tools such as worn drill bit edges and chipped edges on taps. The vision system allows access to 100

tool profiles which can be called by index position or program control registers

accessed with binary coding.

Other features include:

- Microsoft Windows7 or Windows10 Pro Operating Systems

- Support for up to 4 High-Speed Progressive Scan Sensors

- Gig-E Vision or USB3 Sensor Connections

- Touch Screen Input for Setup and Function Control

- High Resolution Graphics (Digital and Analog Outputs)

- USB ports for connecting Keyboard and Mouse

- EtherNet Port (100/1000 MB and assignable IP address for

system)

- Many Special Image Processing Functions (many

Patented or Patent Pending)

The

machine vision system allows for the simultaneous acquisition of two

progressive-scan sensors at a time. Each sensor can be mounted up to 100 M

(Gig-E Vision) or 20 M (USB3) from the PVS-80

or PVS-100 image processing enclosure.

Phoenix Imaging also offer a compact integrated

sensor/processor module (SCNC) which provides a cost effective solution for

customers that only require knowledge that the tool has experienced damage and

not wear prediction.

|

The

typical system is based on the PVS-80 vision controller,

with one or more vision sensors (mounted inside environmental enclosures), and one or

more corresponding LED lighting units. Backlighting is used for tool

silhouette and ring lighting is used to highlight leading edge imperfection when

viewed down the tool axis. The PVS-80 is

pre-mounted inside a NEMA type-4 (IP65) electrical enclosure and is available

with a 15" TFT flat panel touch screen display for parameter adjustment and

inspection information. The system can accommodate direct inputs and outputs

for communication of inspection conditions to external devices. The Standard configuration

provides 8 inputs and 8 outputs connected through industrial standard optical

isolated relay modules. A special version PVS-85 is designed for OEM

customers that would like to mount the image processor inside their own

electrical enclosures.

The

typical system is based on the PVS-80 vision controller,

with one or more vision sensors (mounted inside environmental enclosures), and one or

more corresponding LED lighting units. Backlighting is used for tool

silhouette and ring lighting is used to highlight leading edge imperfection when

viewed down the tool axis. The PVS-80 is

pre-mounted inside a NEMA type-4 (IP65) electrical enclosure and is available

with a 15" TFT flat panel touch screen display for parameter adjustment and

inspection information. The system can accommodate direct inputs and outputs

for communication of inspection conditions to external devices. The Standard configuration

provides 8 inputs and 8 outputs connected through industrial standard optical

isolated relay modules. A special version PVS-85 is designed for OEM

customers that would like to mount the image processor inside their own

electrical enclosures.